After the devastation caused by the very late frost to the early growth in 2011 Steve looked at various ways of preventing future frost damage. With a small vineyard, that is relatively close to other people, he had to have a solution that was environmentally friendly, cost effective, practical and quiet.

The common methods used in vineyards include lighting fire buckets or using heating devices to warm the air near the vines, this was not a practical solution as it relied on someone realizing that frost was about to form, getting up (if it was during the night), lighting the fires and also the impact on neighbours of the smoke from the fires was not an acceptable consideration.

Another common method used in larger vineyards is to use a fan to keep the air moving (one of the criteria for frost to form is little air movement) Unfortunately cost and noise ruled that out as a practical option at Little Oak Vineyard.

Methods used to keep the air moving at some vineyards range from fixed fans (as shown on the right) to getting a helicopter to hover low over the vineyard to disturb the air around the vines.

The method considered practical for Little Oak Vineyard was one of spraying the vines during frost conditions and using the latent heat produced as ice forms from water to protect the plant at the critical time. When you use water to prevent frost damage, you are using the energy that water releases when it freezes and changes state from a liquid to a solid. This keeps the temperature in the ice at the freezing point of 0c. As long as you keep the ice wet, the ice temperature will stay at 0c. If the ice dries out and water starts to evaporate from the ice, the ice will get colder than the air temperature as it evaporates. The vine leafs do not start to suffer cell damage from frost until they reach –

It is important that the system only switches on at the right time –

It is also essential that the system stays on for long enough to get through the critical temperature window, an adequate supply of water is a must.

The size of the water droplets falling on the plant is also critical, if the droplet is too small it will have negligible effect, if too big a droplet then its a waste of water which just results in a soggy vineyard. After much research a sprinkler head was found that had been developed for use in vineyards, it sprays a droplet size that has been optimized for vine frost control in a narrow track to help prevent water wastage.

Flipper and water consumption considerations

Water consumption rate is an important consideration in the design of a frost protection system. Each flipper head uses water at the rate of 30 l/h. To protect the area covered by the original 400 vines of the vineyard required 240 flipper heads, a total water requirement of 7200 l/h.

The mains water supply to the vineyard delivers about 3000 l /h to the water tank.

The tank holds 16,000 l so it can be calculated that the water will last for 3.8 hours before the main tank runs dry.

In order to try the system a large paddling pool was purchased, which holds 16,000 l of water, at £300 it helped keep the system price down. A digger was hired and a level base prepared for the pool at the highest point of the vineyard.

A full flow ball cock ensures that the water supply starts topping up the pool as the level drops.

After much experimentation a suitable pump was sourced that would both self prime and was capable of delivering the flow rates and the pressure required. Plumbing consisted of a 100mm pipe across the top of the vineyard fed from the pump (through a 130 micron filter) with a tee off via a saddle clamp to feed every row of vines via a 20mm pipe.

Testing the Frost Sprinkler System

The black pipe at the end of the row of vines is the 20mm pipe running down the row of vines feeding the flippers

In the pictures above you can clearly see that the flippers are spraying droplets rather than a mist over the vines, this was found to be very important. A mist (rather than droplets) does not work well.

An aluminium plate was fixed to the inside and outside of the pool to allow installation of a ball cock to control the incoming water into the tank and to allow a 100mm bulkhead fitting to the side of the pool to take the water from the pool to the pump. A low voltage solenoid valve was fitted down line from the pump to shut off the water supply to the vineyard when the pump was not running The solenoid was wired in parallel (but isolated due to the differing voltages) to the pump to open as soon as the pump runs). The head of water in the tank ensured that the pump was always full and ready to run.

The units standing on the platform next to the pool is the mains supply, the power supply for the frost detection unit and the frost control box (This is of course covered to protect the unit from the weather.

Frost Protection Control System

It was decided to design and produce a control system that would allow the system to monitor the local conditions and when frost was going to happen switch the pump on automatically. This was quite a complicated problem to sense, as frost is not solely dependent on air temperature, it also needs the right amount of humidity in the air, the dew point to be in a certain range and the wind to be light

The control panel measures all of these constantly, when all the variables are right it switches the pump on, it then checks every 5 minutes to see what is happening, if the conditions for frost have gone then it will switch the unit off, if they continue to be in the parameters window for frost the unit continues to run for another 5 minutes.

It monitors and acts upon frost conditions without any further human intervention.

Frost system sensors and control system electronics

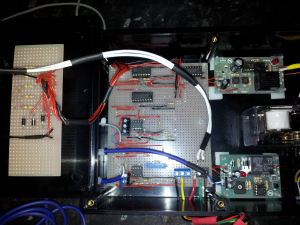

The control unit is powered via a 500w switched mode computer power supply for maximum safety, reliability and to ensure a cost effective source of control power. The picture below shows the control unit, the sensors for temperature, dew point and wind speed, and the power supply ready for installation.